TranStarX Photoelectric Glass: Application Implementation Path

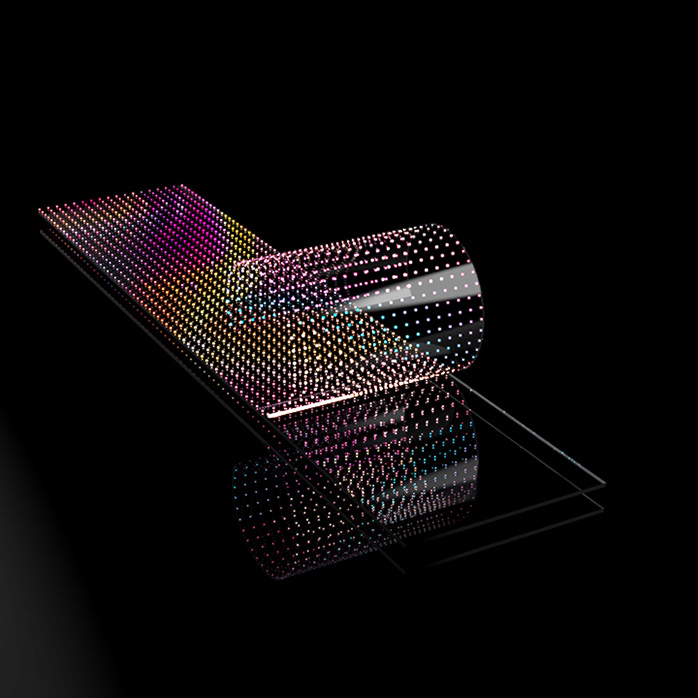

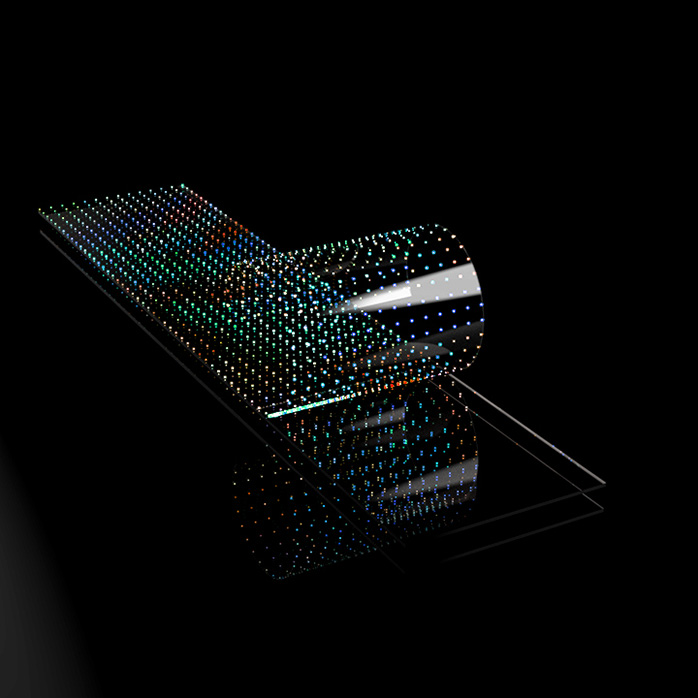

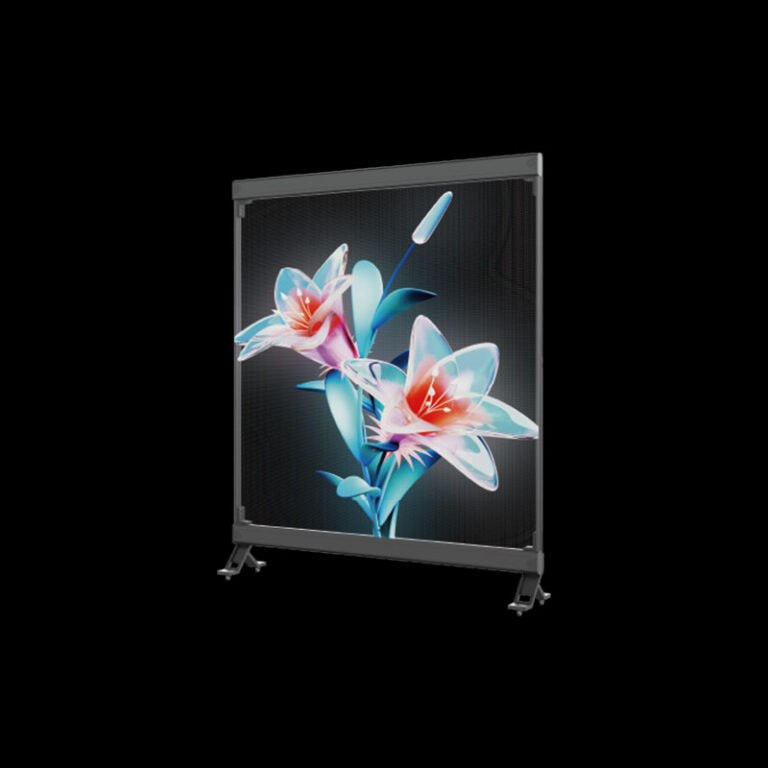

As a technology-driven enterprise under Hainan Xinshi Group, focusing on the LED transparent display field, TranStarX (Shenzhen) Co., Ltd. has developed its photoelectric glass series (including models TSX-LEGL-P3.91, TSX-LEGL-P5.0, TSX-LEGL-P6.25) based on independently developed “LED crystal core + double-layer tempered glass” composite packaging technology, impact-resistant protection technology, and high-stability driver system. With core advantages of “92% ultra-high light transmittance, IP65 outdoor protection rating, resistance to temperatures from -30℃ to 60℃, and direct replacement of traditional architectural glass,” it breaks the application boundary between “display function and architectural glass” and realizes the integrated triple functions of “architectural decoration + digital display + energy-saving protection.”

Widely applicable to commercial building curtain walls, outdoor advertising light boxes, cultural museum exhibition walls, transportation hub partitions, etc., this product provides users with “safe, durable, energy-efficient, and scenario-based” digital display solutions. Below is a detailed explanation of the photoelectric glass implementation path from four dimensions: application scenarios, scheme design, implementation guarantee, and core value.

I. Core Application Scenarios and Customized Scheme Design

Based on the product characteristics of photoelectric glass—”architectural-grade safety standards, full-environment adaptability, and large-size splicing”—differentiated application schemes are customized to address core needs of different scenarios (e.g., architectural function integration, outdoor durability, safety protection), ensuring product performance deeply aligns with scenario value.

(I) Commercial Building Curtain Wall Scenarios: Creating City Landmarks “Transparent & Elegant by Day, Dynamically Illuminated by Night”

1. Scenario Pain Points

Traditional commercial building curtain walls (e.g., mall facades, office building podiums, high-end hotel exteriors) mostly use ordinary tempered glass, only providing lighting and decorative functions. To achieve nighttime illumination or advertising display, additional outdoor LED screens must be installed, which brings issues such as “thick screens damaging the overall architectural style, low transmittance blocking indoor lighting, need for structural reinforcement for installation, and high post-maintenance costs.” Moreover, ordinary LED screens have poor resistance to harsh outdoor environments and are prone to malfunctions.

2. Photoelectric Glass Scheme Design

- Product Selection: Prioritize photoelectric glass TSX-LEGL-P5.0 (92% transmittance, maximum single-piece size 1.2m×2.4m) for medium-sized commercial curtain walls (50-200㎡). For curtain walls over 10m high or in high-wind environments (e.g., coastal commercial buildings), select enhanced TSX-LEGL-P6.25 (wind pressure resistance up to 1.5kPa, far exceeding the 1.0kPa standard of ordinary glass). For high-end commercial properties (e.g., luxury malls), recommend TSX-LEGL-P3.91 with higher resolution (67,600 pixels/㎡) for more delicate nighttime illumination.

- Installation Method: Adopt integrated curtain wall installation—directly replace traditional curtain wall glass and embed it into the existing curtain wall keel structure (supporting both hidden-frame and exposed-frame curtain wall systems), no additional display screen brackets required. During installation, photoelectric glass is fixed to the keel with special structural adhesive, and edges are sealed with silicone sealant for waterproofing, ensuring the overall curtain wall’s water and air tightness. With a weight of ≤25kg/㎡ (equivalent to ordinary double-layer tempered glass), no extra structural reinforcement is needed, reducing installation costs by 30% compared to the “traditional glass + outdoor LED screen” combination.

- Content & Function Design:

- Time-phased Dynamic Content: Keep high transparency during the day (8:00-18:00), only displaying low-brightness brand logos or static public welfare slogans (brightness adjusted to 1200nits) to avoid affecting indoor lighting and exterior texture. Increase brightness to 3000nits at night (18:00-22:00) to play dynamic light shows, commercial event promotions (e.g., mall sales, brand launch previews), or city cultural content (e.g., local folk animations, festive scenes), with images highly matching the building’s outline to create an immersive visual landmark.

- Intelligent Environment Adaptation: Equip temperature-sensing + light-sensing dual-control modules to monitor outdoor temperature, humidity, and light intensity in real time. Activate the screen’s heat dissipation system (built-in micro cooling fans) in high temperatures (≥40℃) and heating protection in low temperatures (≤-10℃) to prevent glass condensation or lamp bead freezing damage. Automatically increase brightness to 3500nits in strong light (≥50,000lux) for clear visibility, and reduce brightness in low light to balance energy efficiency and visual experience.

- Advertising Revenue Operation: Support dividing the curtain wall into multiple advertising zones. Through TranStarX’s “Curtain Wall Advertising Management System,” advertising spaces can be rented out, and brands can remotely deliver content and view real-time playback data (e.g., playback duration, coverage). This brings additional advertising revenue to commercial properties (reference case: 100㎡ photoelectric glass curtain wall generates annual advertising revenue of 600,000-1,200,000 yuan).

3. Scenario Value

- Integration of Architecture & Display: Photoelectric glass directly replaces traditional curtain wall glass, realizing “architectural + display function integration” and avoiding the awkward disconnection between screens and buildings, enhancing the commercial property’s exterior grade by 40%. The 92% high transmittance ensures unobstructed indoor lighting during the day, saving 25% on daytime lighting costs compared to traditional outdoor LED screens (≤50% transmittance).

- Balance of Durability & Energy Efficiency: IP65 protection rating and temperature resistance adapt to complex outdoor environments, with a service life of over 10 years (far exceeding the 5-year life of ordinary outdoor LED screens). The low-power design (daily power consumption ≤6kWh/㎡) saves 55% energy compared to traditional outdoor LED screens, significantly reducing long-term operating costs.

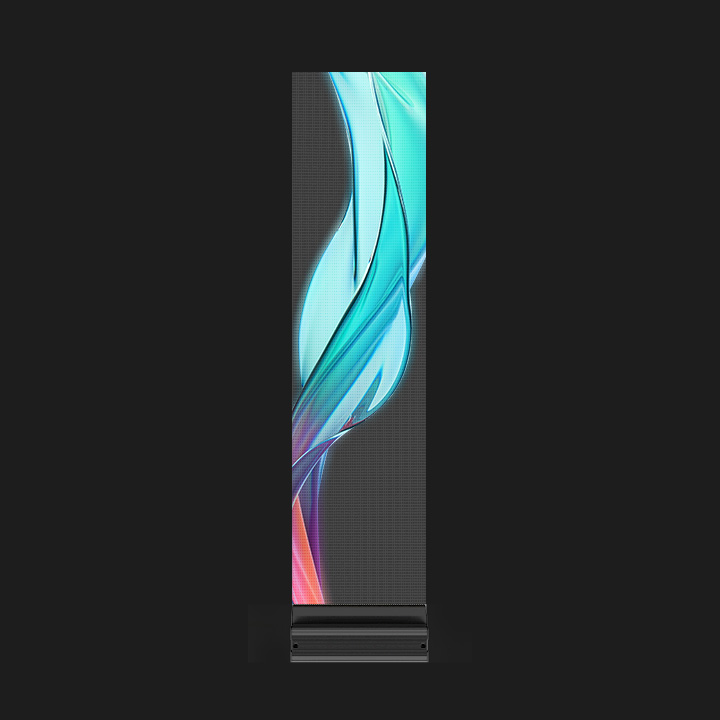

(II) Outdoor Advertising Light Box Scenarios: Building “Safe, Durable, HD & High-Brightness” Outdoor Media Carriers

1. Scenario Pain Points

Traditional outdoor advertising light boxes (e.g., subway entrance light boxes, business district column light boxes, highway billboards) mostly use “acrylic panel + fluorescent tube” or “ordinary glass + LED backlight” structures, with issues such as “low image clarity, insufficient brightness (≤2000nits), weak impact resistance (easy to break), and manual disassembly required for content replacement.” Especially in rainy, high-temperature, or cold areas, light boxes are prone to water short circuits and tube aging, leading to frequent maintenance and high costs.

2. Photoelectric Glass Scheme Design

- Product Selection: Use photoelectric glass TSX-LEGL-P3.91 (3200nits brightness, high resolution, suitable for close-range viewing) for light boxes in high-foot-traffic areas (e.g., subways, business districts), with sizes customized to light box structures (0.8m×1.5m to 1.2m×2.4m). For long-distance viewing scenarios (e.g., highways, outdoor columns), select TSX-LEGL-P6.25 (3500nits brightness, 50m visible distance), supporting multi-piece splicing for large advertising images (maximum 10m×5m large light boxes).

- Light Box Structure Design: Adopt “photoelectric glass + metal frame” integrated structure. The metal frame uses corrosion-resistant aluminum alloy (with fluorocarbon coating, 1000-hour salt spray resistance), with built-in channels for power and signal lines. After embedding photoelectric glass into the frame, edges are sealed with waterproof strips, and a waterproof heat dissipation backplane (IP66 protection) is added to the back, ensuring the light box is rainproof, dustproof, and corrosion-resistant for full outdoor use.

- Content & O&M Design:

- HD Dynamic Content: Support 4K HD advertising videos (e.g., automotive, FMCG brand ads) with 90% color reproduction (complying with Rec.709 color gamut) and ≥92% brightness uniformity. Even in midday strong light, images remain clear, increasing attention by 60% compared to traditional light box ads.

- Remote Content Update: Equip TranStarX’s “Outdoor Advertising Cloud Publishing System.” Operators can remotely push content via computer/mobile, supporting scheduled publishing (e.g., commute-related ads during morning peak, catering ads during evening peak). No on-site manual disassembly is needed, improving content update efficiency by 95% and saving 40%-60% annual labor and material costs.

- Intelligent Fault Monitoring: Built-in intelligent monitoring chips in the screen real-time feed back lamp bead status, voltage, temperature, etc. The background automatically alerts when faults occur (e.g., individual lamp bead damage, short circuit), and the O&M team can accurately locate faults via the system, reducing maintenance response time to within 2 hours (urban areas) with an annual failure rate ≤1.2%.

3. Scenario Value

- Advertising Effect Upgrade: HD high-brightness dynamic content improves ad information transmission efficiency by 50%, increasing brand exposure conversion rate by 35% compared to traditional light boxes. Impact and corrosion resistance ensure stable operation in harsh outdoor environments, reducing advertising revenue losses from downtime.

- O&M Cost Optimization: Remote content management + intelligent fault monitoring significantly reduce manual maintenance frequency. With a 10-year service life and low-power design, long-term comprehensive costs are reduced by over 50% compared to traditional light boxes.

(III) Cultural Museum Exhibition Wall Scenarios: Realizing “Cultural Relic Protection + Cultural Display” Safe & Smart Exhibitions

1. Scenario Pain Points

Exhibition walls in museums and cultural centers mostly use traditional brick or ordinary glass structures, only providing space division and decoration. To display cultural content related to relics (e.g., historical background, archaeological stories, relic details), additional display boards or ordinary LED screens are needed, which bring issues such as “thick screens occupying exhibition space, uncontrollable light intensity (easy to damage relics), and excessive electromagnetic radiation”—failing to meet the strict requirements of Museum Lighting Design Standards for relic protection.

2. Photoelectric Glass Scheme Design

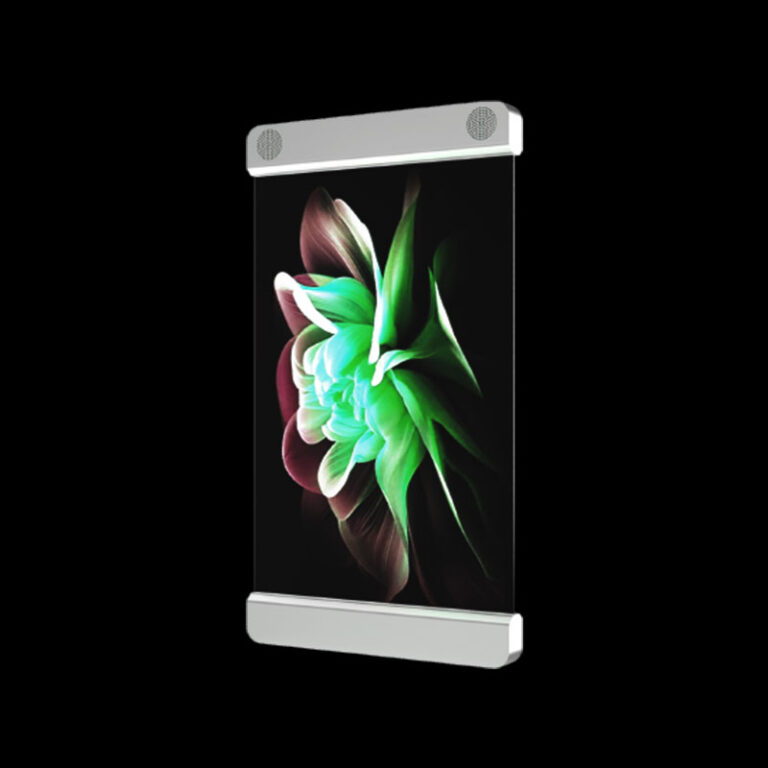

- Product Selection: Use indoor-specific photoelectric glass TSX-LEGL-P3.91 (adjustable brightness 500-1500nits, no electromagnetic radiation), with sizes customized to exhibition wall layouts (0.6m×1.0m to 1.2m×2.4m). For exhibition walls displaying precious relics (e.g., calligraphy, silk fabrics), select low-blue-light versions (blue light ratio ≤20%) to avoid long-term damage to relics.

- Installation & Exhibition Design:

- Safe Exhibition Wall Construction: Embed photoelectric glass into the museum’s exhibition wall keel to form a “transparent exhibition wall.” Reserve relic display space (e.g., small relic cabinets) inside the wall, and play relic-related cultural content on the photoelectric glass outside (e.g., “ancient painting restoration animations” for calligraphy exhibition walls, “bronze casting process videos” for bronze exhibition walls). This realizes layered display of “physical relics + digital content” without blocking relics, while enriching exhibition information.

- Lighting & Radiation Control: Link photoelectric glass brightness to ambient light via an intelligent control system. When light intensity near the wall exceeds relic protection standards (e.g., ≤50lux for calligraphy, ≤30lux for silk), the screen automatically reduces brightness to below 300nits. The non-electromagnetic radiation design (electromagnetic radiation ≤0.1μT) fully complies with Museum Building Design Standards (JGJ 66-2015) for relic protection, avoiding potential radiation damage to relics.

- Interactive Cultural Experience: Integrate capacitive touch functions—visitors can tap the screen to “zoom in on relic details” or “switch cultural content from different historical periods” (e.g., clicking on an ancient map on the museum wall to view corresponding historical events). Multi-language content switching (Chinese, English, Japanese, etc.) is supported to meet the needs of international visitors.

3. Scenario Value

- Exhibition Experience Upgrade: Layered “physical + digital” display improves visitors’ understanding of cultural content by 45%, and increases youth interaction rate by 55% compared to traditional exhibition walls. The transparent, thin design occupies no exhibition space, maintaining the museum’s simple and solemn exhibition style.

- Relic Protection Compliance: Low adjustable brightness, no electromagnetic radiation, and low blue light meet cultural museum relic protection standards, balancing exhibition effects and relic safety, and avoiding exhibition rectification due to non-compliant equipment.

(IV) Transportation Hub Partition Scenarios: Creating Multi-Functional Transparent Barriers for “Space Division + Information Guidance”

1. Scenario Pain Points

Space partitions in transportation hubs (airports, high-speed rail stations, subways) mostly use ordinary glass, only providing area division and safety guarantees. To deliver information to passengers (e.g., flight/train schedules, in-station navigation, public welfare prompts), additional information screens or signs are needed, leading to issues such as “dispersed information (passengers need to check multiple signs frequently), screens occupying space, and inconsistency with partition style,” affecting space utilization and passenger flow efficiency.

2. Photoelectric Glass Scheme Design

- Product Selection: Use transportation hub-specific photoelectric glass TSX-LEGL-P5.0 (impact resistance ≥50kg/cm², 92% transmittance), with sizes customized to partition heights (2.0m×1.0m to 3.0m×1.5m). For partitions in high-foot-traffic areas (e.g., security checkpoints, ticket gates), select anti-glare versions (glare value ≤19) to avoid screen reflection affecting passengers’ vision.

- Installation & Information Design:

- Multi-Functional Partition Construction: Use photoelectric glass as space partitions in transportation hubs (e.g., partitions between airport check-in and waiting areas, waiting hall partitions in high-speed rail stations) to replace traditional ordinary glass. The partition realizes both area division and real-time information display via photoelectric glass, no additional information screens required, improving space utilization by 30%.

- Dynamic Information Guidance: Customize information content by area—airport partitions display “real-time flight dynamics” (flight number, departure time, gate, delay prompts) and “in-station navigation maps” (click to view gate, restroom, convenience store locations); high-speed rail partitions display “train schedules,” “gate change notifications,” and “safe travel prompts.” Information updates automatically every 30 seconds to ensure passengers get the latest dynamics.

- Priority Emergency Information: Set an “emergency information priority mechanism.” In case of flight delays, train delays, or safety warnings, the system automatically pauses regular information and prioritizes emergency notifications (e.g., “Flight XXX delayed by 2 hours due to weather; please go to Service Area XX for rest”) with voice broadcasts, ensuring passengers receive key information promptly and improving emergency response efficiency.

3. Scenario Value

- Passenger Flow Efficiency Upgrade: Integrated information partitions reduce passengers’ information acquisition time by 40%, minimizing missed flights/trains due to delayed information checks. The transparent design maintains the sense of openness in hub spaces, avoiding the sense of oppression from partitions.

- Operating Cost Optimization: Photoelectric glass replaces the “ordinary glass + information screen” combination, reducing equipment procurement and installation costs. The low-power design and 10-year service life reduce long-term operation and maintenance costs by 45% compared to traditional schemes.

II. Full-Process Guarantee for Scheme Implementation

To ensure efficient implementation and stable operation of the photoelectric glass application scheme, TranStarX has established a full-cycle service system covering “demand research – scheme design – production and delivery – installation and commissioning – after-sales maintenance,” providing professional and standardized support for customers.

(I) Early Stage: Demand Research and Scheme Customization

- In-Depth Scenario Research: Form a special team of “product consultants + architectural engineers + technical specialists” to conduct on-site surveys. For commercial curtain wall scenarios, measure building keel sizes and evaluate outdoor environment parameters (e.g., annual temperature, humidity, wind force); for cultural museum scenarios, test light intensity and confirm relic protection standards; for transportation hub scenarios, count passenger flow density and clarify information display needs. A Photoelectric Glass Scenario Demand Report is formed as the basis for scheme design.

- Visual Scheme Output: Output 3D scenario models and effect preview videos (e.g., curtain wall day/night effects, relic-content overlay effects on exhibition walls) based on research results. Provide 1:1 photoelectric glass samples (e.g., 30cm×30cm TSX-LEGL-P5.0 samples) for customers to test transmittance, impact resistance, and display effects. Optimize scheme details (e.g., adjust product models, refine content logic) based on customer feedback to ensure alignment with actual needs.

(II) Middle Stage: Production, Delivery, Installation, and Commissioning

- Standardized Production and Quality Inspection: Launch the production process of “glass cutting – LED crystal core packaging – composite lamination – protection treatment” according to the product model and parameters specified in the scheme, strictly implementing three-level quality inspection: incoming raw material inspection (tempered glass impact resistance, LED lamp bead performance), in-production patrol inspection (lamination accuracy, waterproof sealing), and outgoing finished product inspection (transmittance, brightness, protection rating, electromagnetic radiation). Ensure each piece of photoelectric glass meets architectural-grade safety standards and display performance requirements, with a production cycle of 15-25 working days (for regular orders).

- Customized Logistics and Installation:

- Logistics: Use “shockproof foam + wooden frame + dedicated transport rack” packaging, and arrange logistics companies qualified for large glass transportation. Monitor glass status throughout transportation to avoid damage from extrusion or collision.

- Installation: Dispatch professional installation teams with architectural curtain wall or interior decoration qualifications, equipped with dedicated tools (e.g., glass suction cups, sealant guns, laser levels) for on-site service. Strictly follow the Photoelectric Glass Installation Technical Specifications—complete installation and commissioning within 5-10 days for commercial curtain walls, and 2-5 days for outdoor light boxes/cultural museum exhibition walls/transportation partitions. After installation, test screen display effects, waterproof performance (outdoor scenarios), and touch response (interactive scenarios), and issue an Installation and Commissioning Report.

- Customer Acceptance and Training: Invite customers to conduct joint acceptance; sign the Project Acceptance Form after passing. Provide operation training for the customer’s operation team (covering content publishing, brightness adjustment, basic fault troubleshooting), and issue the Photoelectric Glass Operation Manual and Emergency Handling Guide.

(III) Later Stage: After-Sales Maintenance and Operation Support

- Long-Term After-Sales Guarantee: Provide 5 years of free after-sales maintenance (8-year warranty for core components such as LED lamp beads and driver chips), with a 7×24-hour service hotline (400-001-2281). On-site maintenance is provided within 24 hours for outdoor scenarios and 12 hours for indoor scenarios. All replacement parts for maintenance are original genuine parts to ensure quality.

- Regular Inspection and Optimization: Arrange engineers for on-site inspections every six months (quarterly for outdoor scenarios) to check screen operation status, waterproof sealing performance, and line aging. Issue a Quarterly/Semi-Annual Inspection Report. Provide 1 free software upgrade service annually (optimizing the information publishing system and enhancing intelligent control functions) to ensure the scheme adapts to the customer’s long-term operation needs.

III. Core Value Highlights of the Scheme

- Function Integration: Relying on the “architectural glass + LED display” composite process, it realizes the triple integration of “lighting decoration + digital display + safety protection,” meeting multi-scenario needs without additional equipment and breaking the application boundary between traditional display devices and architectural carriers.

- Safety and Durability: Architectural-grade tempered glass substrate + IP65 protection rating + temperature resistance adapt to multi-environments (outdoor, cultural museum, transportation). With a 10-year service life (far exceeding ordinary display devices), it reduces cost losses from frequent replacements.

- Energy Efficiency and Economy: 92% high transmittance saves daytime lighting costs; the low-power design (55% energy saving compared to traditional outdoor LED screens) reduces long-term operating costs. Remote content management + intelligent fault monitoring reduce manual maintenance frequency, delivering significant comprehensive cost advantages.

- Service Professionalism: Provide full-process services from scenario research to after-sales maintenance, including “customized schemes + standardized implementation + long-term O&M,” with professional teams in architecture, technology, and operation to ensure efficient scheme implementation, stable operation, and reduced customer project risks.

Adhering to the concept of “making buildings ‘speak’ and making displays safer,” TranStarX photoelectric glass is committed to creating “safe, energy-efficient, and intelligent” digital display solutions for customers in various industries through technological innovation, promoting the upgrading of architecture, advertising, cultural museum, and transportation fields toward “function integration and intelligent operation.” For further customized schemes or product details, please call the service hotline at 400-001-2281 or visit the headquarters of TranStarX (Shenzhen) Co., Ltd. (Building B, Huada Weixin, Fuqiao Third Industrial Zone, Qiaotou, Fuyong Street, Bao’an District, Shenzhen) for an on-site experience.